Daiwa provides precision parts with our start-to-finish manufacturing system.

Through our own technology and cooperation with partner companies, Daiwa supplies finished products with our start-to-finish manufacturing system.

Shims and spacers

Daiwa manufactures shims and spacers for fine dimensional adjustments. When assembling machinery and equipment, it is sometimes necessary to make fine dimensional adjustments because the assembly does not meet the target dimensions. In such cases, assembly adjustments are made using shims and spacers.

We manufacture very thin to thick shims ranging in thickness from 0.005 mm to 5 mm. We also manufacture shims made of general-purpose material such as SUS304, to those made of special material such as Ti. Titanium is an effective material when magnetic material cannot be used due to application specifications.

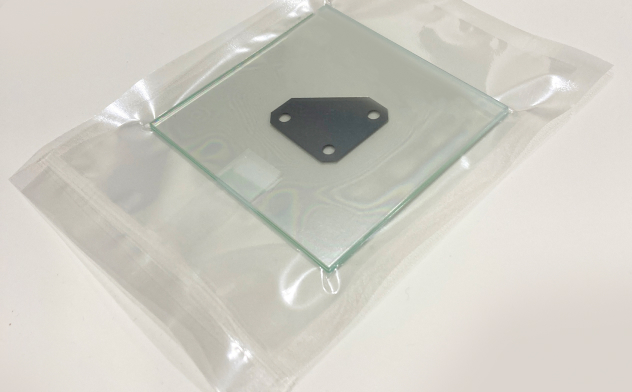

Machining example 01Thin 0.005 mm shim made of Ti material

This shim was produced by etching. With thin metal materials, problems can occur such as distortion or scorching of the machined surface during laser processing or electric discharge wire cutting. In such cases, etching is a very effective manufacturing method because it improves the cleanliness of the machined surface, and suppresses distortion.

Furthermore, special care must be taken when packaging very thin shims. At Daiwa, we place shims on a plate made of plastic material that is cleanroom compatible, and vacuum pack them to ensure safe delivery. These materials are compatible with environmentally controlled substances, and as previously mentioned, can be used for precision equipment such as semiconductor manufacturing equipment because they are cleanroom compatible.

*We supply individually-packaged parts that have been clean washed and vacuum packed.

Optical slits

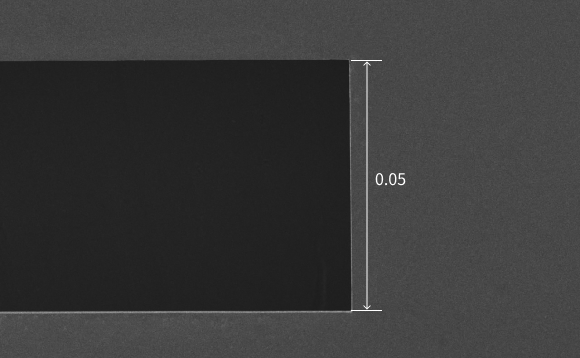

Machining exampleRectangular slit

We manufactured rectangular slits, which are optical components. Optical slits are very thin rectangular holes, and they are used in experiments and optical devices that use light diffraction. They are also integrated into optical systems when monochromatizing light with a monochromator, etc.

In this example, we manufactured a slit with width of 0.01 mm. We used electroforming for the manufacturing method, and Ni for the material. Depending on the application, slits can be manufactured with copper when the magnetism is unacceptable.

We also provide rectangular apertures for variable shaped beams that are integrated into electron optical systems. The hole corner R of these apertures must be as small as possible. The sharp corner R is kept to 0.001 mm or less.