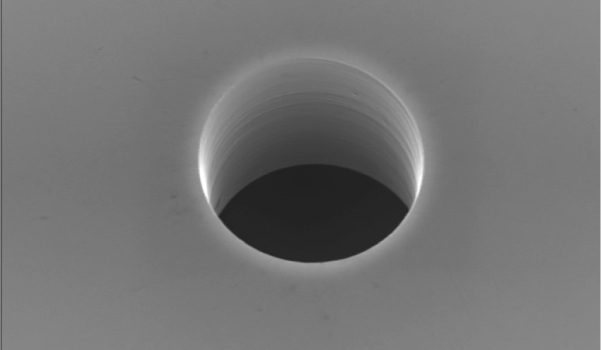

Micro electrical discharge machining (ultra-fine holes)

The ultra-fine hole machining by micro electrical discharge machining can be used for conductive material of φ0.002 mm (φ2 μm). Ultra-fine hole machining is normally difficult, but with our in-house ultra-fine discharge electrodes, we are now able to machine holes this small. This machining is mostly used to produce apertures for electron microscopes, X-ray shielding pinholes (slits), and for optical components such as collimators or orifices. These parts are made of various materials, including stainless steel, tungsten, tantalum, molybdenum, and other metals with high-melting point, as well as precious metals such as platinum and its alloys. These parts are used in equipment such as electron microscopes, semiconductor inspection equipment, and X-ray and synchrotron radiation.

Do you have such concerns with

micro electrical discharge machining?

- Concern 01

I was considering having holes drilled by cutting, but I was refused because machining was not possible.

- Concern 02

I want to drill φ0.05 holes in stainless steel, but the holes will be too small to be machined.

I was considering having holes drilled by cutting, but I was refused because machining was not possible.

- Concern 03

I want to drill difficult-to-cut materials such as molybdenum, tungsten, tantalum, Inconel, Hastelloy, and titanium, but I can’t find a company to handle it.

- Concern 04

I need ultra-fine holes of φ0.010 or less, but can’t find a company to handle it.

What is micro electrical discharge machining?

Discharge machining is a method of machining in which a discharge phenomenon occurs between a metal material and an electrode.

A discharge electrode is placed close to the metal material, and electric energy applied to the electrode generates discharge, causing the metal material to melt due to heat. Cooling and dispersion are then repeated continuously to gradually machine the metal material. Using this method, difficult-to-cut, high-hardness metals (e.g., carbide, tungsten) can be machined easily, and machining is possible as long as the material is electrically conductive.

Ultra-fine hole machining by ultra-micro electrical discharge machine

Requirements for micro electrical discharge machining

Machining high-hardness metals and difficult-to-cut materials can be troublesome, but some applications require materials that are difficult to handle.

Electron microscopy requires high melting point, non-magnetic materials, and therefore require the machining of pure metals such as molybdenum, tantalum, or tungsten.

At Daiwa, we use electric discharge machining for the fine machining of pure metals.

Electric discharge machining is suitable for machining electrically conductive materials, and it may be possible to machine high-hardness materials and difficult-to-cut materials into the desired shapes.

Features of Daiwa Techno Systems micro electrical discharge machining

Daiwa’s electric discharge machining (EDM) has been adjusted so that materials can be machined in a finer area than general EDM, making it suitable for ultra-fine hole machining.

Since we routinely machine holes of φ0.005 mm (φ5 μm), we have a track record of machining holes with minimum diameter of φ0.002 (φ2 μm).

In addition, all of our electrodes are machined in-house using our proprietary discharge electrode manufacturing technology. We can manufacture electrodes with thickness of φ0.001 mm or less, and we can machine ultra-fine holes by combining machine adjustments with our thin electrode manufacturing technology.

Accuracy of Daiwa Techno Systems micro electrical discharge machining

| Min. hole diameter | φ0.002 mm (φ2 μm) |

| Hole diameters Daiwa specializes in | φ0.005 (φ5 μm) to φ0.500 (φ500 μm) |

| Depth accuracy | (Hole depth L/hole diameter D) = approx. 1 to 10 |

| Materials Daiwa specializes in | Molybdenum, tantalum, tungsten, titanium, Inconel, platinum, stainless steel, etc. |

Frequently asked questions about micro electrical discharge machining

Can you machine any metal?

開くWe can generally machine any metal, but we specialize primarily in pure metals such as molybdenum, tantalum and tungsten.

We can also machine general materials such as stainless steel, but we are not so good at handling soft materials such as aluminum or brass.

What is the minimum hole diameter? What is the maximum hole diameter?

開くThe minimum hole diameter is φ0.002, but we can stably machine holes with diameter of φ0.005 or more.

The maximum hole diameter is up to approximately φ2 mm, but we recommend another machining method for this size.

We specialize in machining holes with diameter in the φ0.005 (φ5 μm) to φ0.500 (φ500 μm) range.

I need deep holes, but how deep can you make them?

開くIt depends on the hole diameter, but the maximum depth is approximately 10 times the hole diameter.

Can you provide materials and blanks?

開くYes, we can. In the event of a failure, we ask that you provide spares.