Manufacture of electron guns for electron microscopes

Daiwa was established in 1967 as a manufacturer of filaments for electron microscopes. For nearly half a century, Daiwa has been supplying products with stable quality and quantity to electron microscope manufacturers around the world.

Thermal-electron guns

These are called “thermal-electron gun” because they use thermal energy to release electrons. Filaments made of thin tungsten wire as the cathode material are common, and most electron microscopes are equipped with this type.

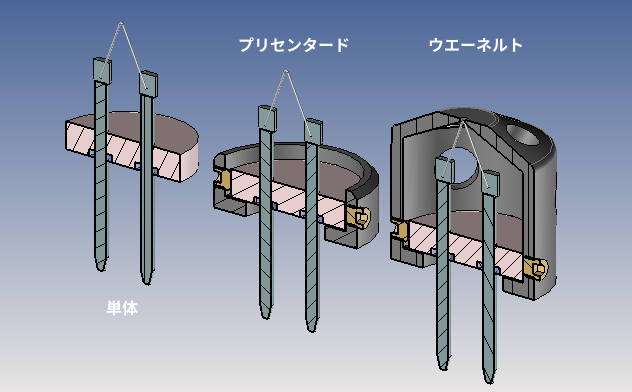

Features of Daiwa Techno Systems thermal-electron guns (stand-alone/pre-centered/integrated with Wehnelt)

- Pre-centered type electron guns do not need to be centered, and can be installed easily in equipment.

- With electron guns with integrated Wehnelt electrodes, not only is there no need for the user to perform Wehnelt cleaning, but they are more convenient due to reduced risk of filament damage. * See schematic diagram.

- In addition to replacement filaments, we also assemble and manufacture electron gun units including extraction electrodes, etc.

Stable quality

Use of high-quality materials

The use of tungsten wire alone is useless as an electron gun. High-quality materials are required to deliver performance in harsh environments of approximately 2,500°C.

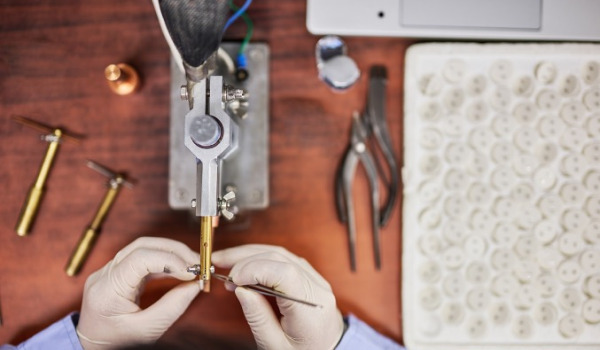

Independent development of dedicated filament welding machine

Daiwa performs precision welding from ultra-fine wire with diameter of φ0.02 to very thick wire with diameter of φ0.5. We design and use our own welding and inspection jigs in order to make them suitable for manufacturing different shapes of filament.

Work of skilled craftsmen capable of meeting various requirements

Our craftsmen control and verify the melt state for fine welding. As experts, they are often able to see things that no one else can.

Various core technologies and know-how specialized for electron microscopes

Daiwa did not originally operate as a welding shop or cutting shop, but as a “filament shop for electron microscopes.” As industry, government, and academia have researched and developed electron microscopes since the end of World War II, we have helped them implement many technologies.

High-precision dimensional inspection and thorough external inspection

Thermal-electron guns are often replaced directly by users. We pay attention not only to performance, but also to appearance.

Support with prototype development

You can rely on Daiwa to perform testing under various conditions, such as wire material, wire diameter, and shape, as we have an extensive stock of materials and experience. We also have an extensive track record of manufacturing low-volume ceramic forming that does not require molds, as well as modifications to customers’ existing filaments.

Ability to respond to a wide range of issues from mass production to overseas transactions

Daiwa also has the know-how to shift from prototypes made by skilled craftsmen to multi-line mass production. We can also mass produce 1,000 or 2,000 parts per month. We also have a track record of deals with overseas companies, and so are flexible in dealing with manufactured parts for overseas.

Thermal-electron gun structure and manufacturing features

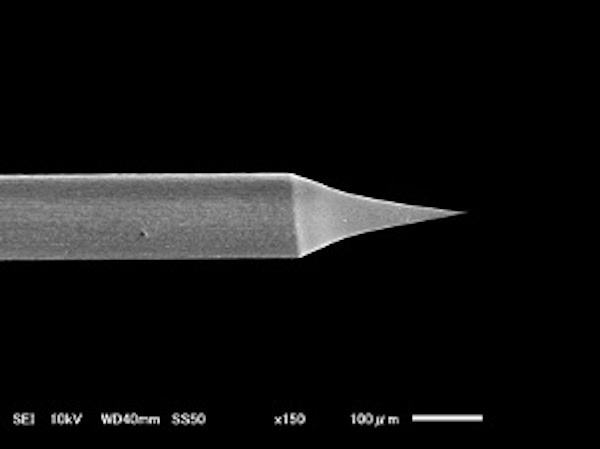

Wide variety of tip shapes (sharp type, semi-pointed type, pointed type)

- KovarIron-nickel alloy that is widely used in vacuum parts because it can be sealed with glass

- Molybdenum (Mo)Non-magnetic, high melting point metal, and high-grade material for electron optics. Molybdenum is used mainly for metallization and brazing for the highest quality products. Welding between materials with high melting point requires advanced technology.

- Tantalum (Ta)Like Mo, tantalum is used in high-grade products as a non-magnetic, high melting point metal, but it can also be secured with a glass seal. Welding between materials with high melting point requires a lot of skill.

- BrazingMetallization is performed on the ceramic surface, and sealing is performed by brazing.

- Glass sealSecures the ceramic and pins using glass (Kovar glass) with adjusted thermal expansion ratio. Glass seal offers benefits in terms of cost and delivery time over brazing, but there are conditions attached to airtightness and operating temperature.

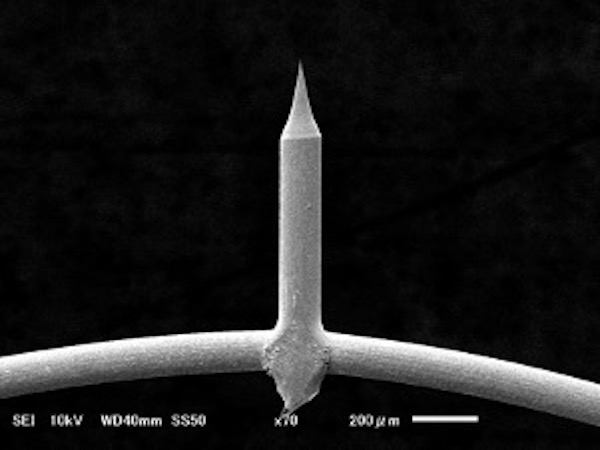

Cold (cathode) field-emission electron guns

Field emission (FE) type emitters require significantly higher machining technology than that used for thermal-electron type filaments. Daiwa’s special technologies, such as welding tungsten together and polishing single crystal chips, are utilized in the most advanced high-end equipment. We help customers manufacture prototypes mainly for research institutes and universities.

Frequently asked questions about electron gun manufacture

The electron beam is not stable.

開くFilaments with poor material quality suffer from electron beam shake and drift.

With those using very poor materials, wire break can occur in no time at all due to cracks.

We use carefully selected parts of high-quality tungsten filament material suitable for electron sources that have been subjected to electron microscopy.

I want you to develop a prototype for me.

開くPrototype projects require insight and experience in both design and production.

With our many years of experience and extensive know-how, we can help you with design and drawings. We can also carry out tests under different conditions (material, filament wire diameter, filament shape, conditioning), and we have a track record of handling prototyping projects for electron microscope manufacturers, universities, and laboratories.

I can’t find anyone to manufacture my parts in small lots.

開くWe specialize in small lot commercial production.

Our accomplished lineup also contains products for dedicated equipment of which there are only 2 to 3 units in the world.

I want to mass-produce parts.

開くWe also supply more than 10,000 mass-produced filaments to customers all over the world. We also have extensive experience in preparing production systems for mass production.