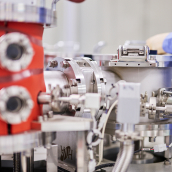

For nearly half a century, Daiwa has been supplying products with stable quality and quantity to electron microscope manufacturers around the world.

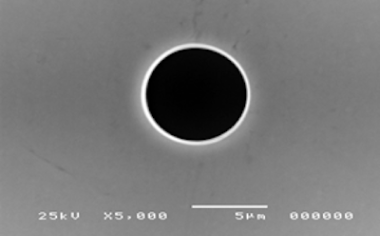

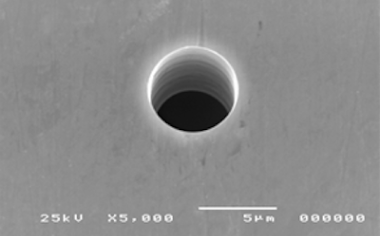

To put it briefly, an aperture for electron microscopy is a thin sheet of metal with micron-sized fine holes. By adjusting the electron beam diameter, the resolution of the electron microscope can be increased to remove excess electrons that reduce contrast.Although it is a small part, the aperture greatly contributes to the performance of the electron microscope.

Manufacture of high-quality apertures for electron microscopes (SEM, TEM, FIB) and semiconductor inspection equipment

We can manufacture aperture plates and orifices using our specialty ultra-fine hole machining technology.

And utilizing our proprietary finishing process and special cleaning technology, we are able to remove nano-level burrs and contaminants.Through this, we are able to obtain high reliability for SEM and TEM electron beam and X-ray apertures.

Apertures

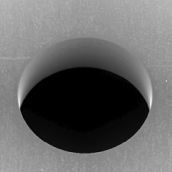

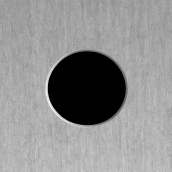

Aperture plate for TEM

Aperture plate for TEM

Mo φ0.006

Mo φ0.005

SUS φ0.01

Photo of packaged aperture

Daiwa Techno Systems apertures

Micro electrical discharge machining (micro-EDM)

Ultra-fine hole machining is normally difficult, but with our in-house ultra-fine discharge electrodes, it is now possible to perform hole machining w...

Utilizing special deburring technology, we are able to perform mirror surface finishing up to the inner surface of fine holes.

Utilizing special cleaning technology, we are able to remove nano-level contaminants.

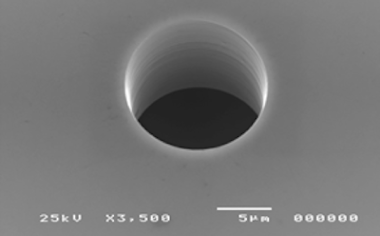

We perform osmium deposition by plasma-enhanced chemical vapor deposition (PECVD) to form stable conductive thin film.

Features of Daiwa Techno Systems apertures

- There are no burrs, protrusions, or flashes.

We perform machining using selected high-quality materials, and remove hole burrs with special deburring technology.

- There are no contaminants or foreign matter.

Daiwa uses its proprietary cleaning technology to thoroughly remove nano-level contaminants.

- Daiwa can handle vacuum baking.

Vacuum baking is carried out to gasify gaseous molecules that remain or are dissolved on the surface or inside material, allowing them to escape the material.

- Daiwa can apply osmium coating.

By applying an osmium coating, a smooth and uniform coating forms on the surface of the aperture to prevent charge-up.

- We vacuum pack our apertures together with a deoxygenating agent and desiccant before shipping.

Because apertures are a thin metal foil, poor packaging can result in damage. This in turn can cause an oxide film to form on the surface, adversely affecting quality. We have developed our own packaging system based on many years of experience.

- Daiwa proposes optimum specifications and machining methods based on customer requirements.

We have accumulated a wealth of machining data through our many years of working with a variety of machining technologies. We propose a machining method and processing accuracy based on the customer’s application and budget.

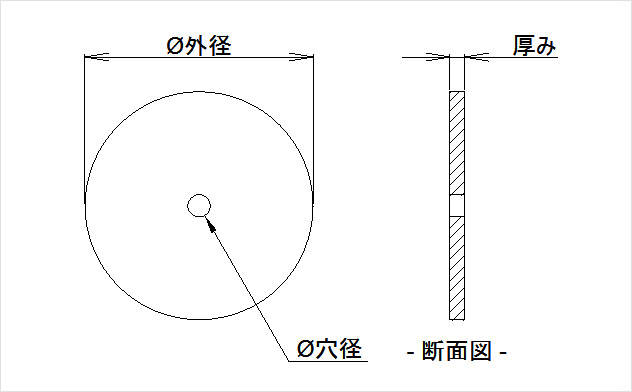

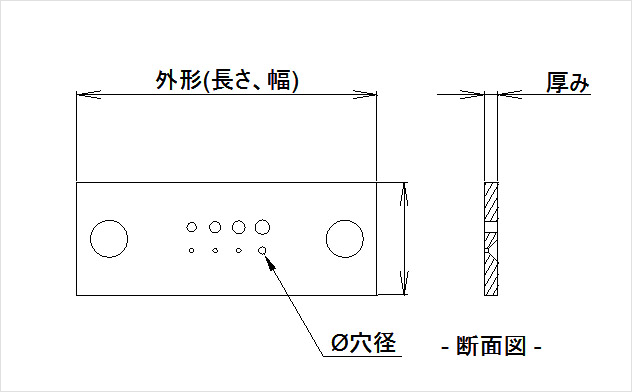

- We handle disc-shaped fixed apertures to variable apertures with multiple holes.

Daiwa Techno Systems can handle disc-shaped fixed apertures to variable apertures with multiple holes. Plate thickness ranges from 0.01 mm to several mm thick, with a minimum hole diameter of φ0.001.

- Hole diameter tolerance is generally ±10% of the hole diameter. We can manufacture parts with hole diameter tolerance as little as ±1 μm.

Hole diameter dimensional tolerance depends on the size of the hole diameter, but the standard tolerance is generally ±10% of the hole diameter. Please contact us for more details.

Aperture manufacturing scope

| Materials | Molybdenum, tantalum, tungsten, platinum, titanium, stainless steel, etc. |

| Exterior [mm] | From φ2 |

| Hole diameter [mm] | From φ0.001 |

| Thickness [mm] | From 0.01 mm |

| Materials | Molybdenum, tantalum, tungsten, platinum, titanium, stainless steel, etc. |

| Length [mm] | From 10 |

| Width [mm] | From 4 |

| Hole diameter [mm] | φ0.001 to φ2 |

| Hole shape | Straight holes, counterbored holes |

| Number of holes | 1 to 20 |

| Plate thickness [mm] | From 0.01 mm |

Frequently asked questions about aperture manufacture

Can you sell parts directly instead of from equipment manufacturers?

開くWe cannot provide the manufacturer’s products directly to third party users. Since we undertake contract machining, we manufacture products from design based on drawings we receive from the customer, or based on the customer’s requirements.

Can you machine slits?

開くIt depends on the size, but we can handle it.

What kind of material can you machine?

開くWe mainly machine metals. We can machine Mo, Ta, W, Pt, Au, Ti, Ni, SUS, Al, Cu and their respective alloys.